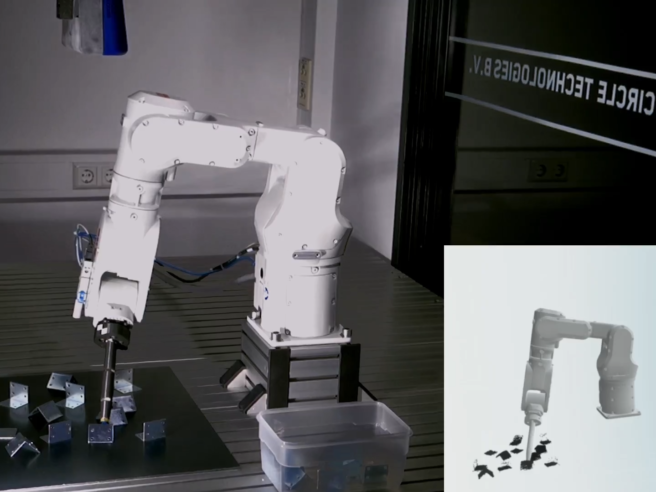

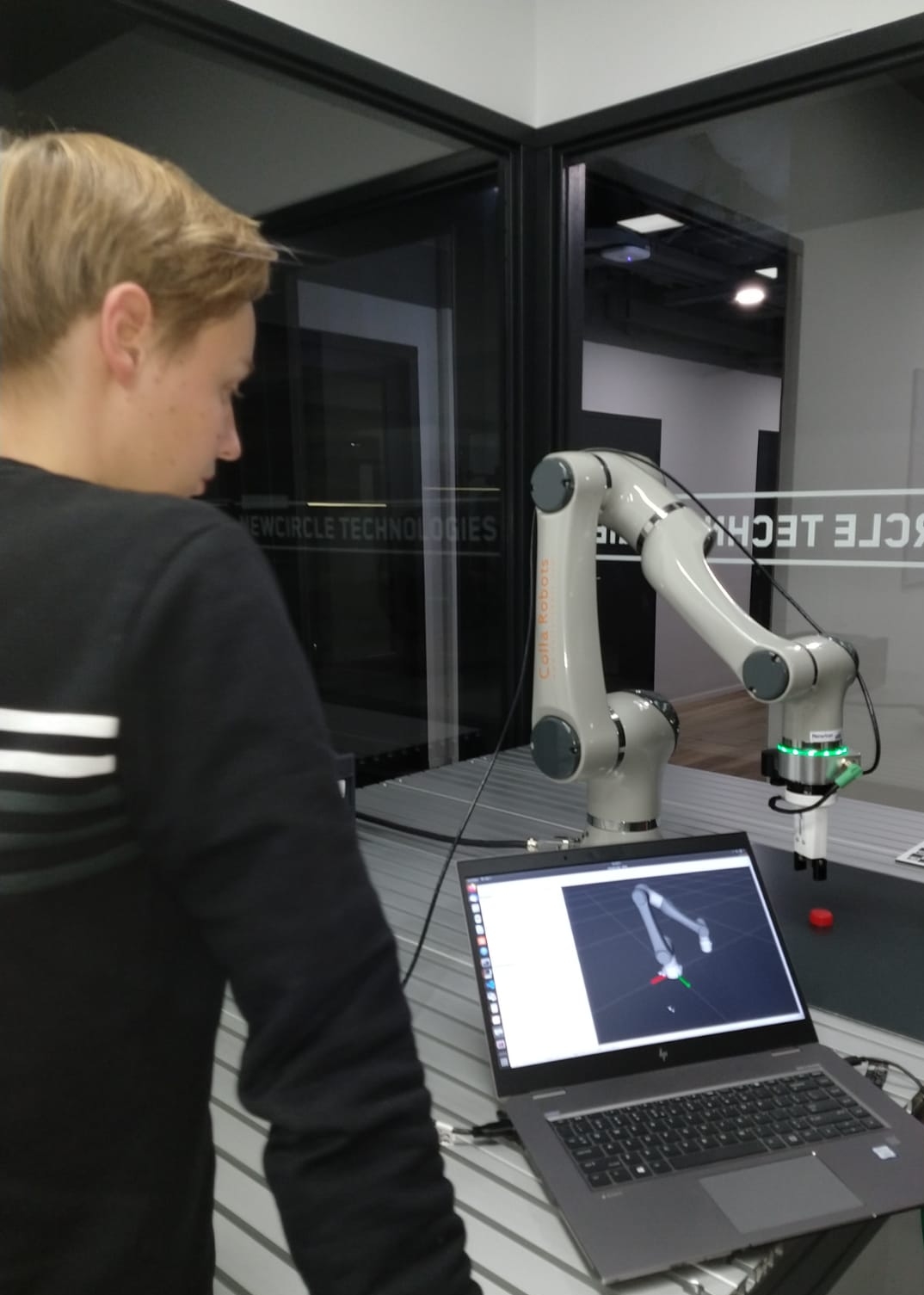

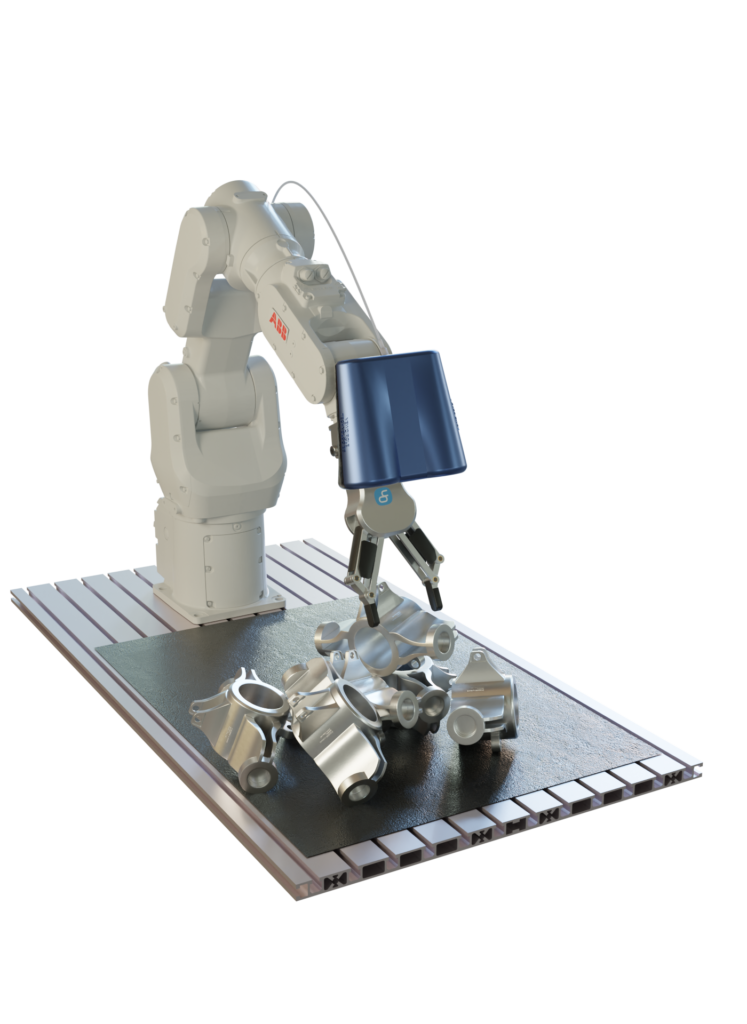

Combining smart detections with robotic manipulation

Modern vision technologies can detect product variations, by combining this with the well-established field of motion control we can robustly handle product versitilty in product actuation and manipulation.

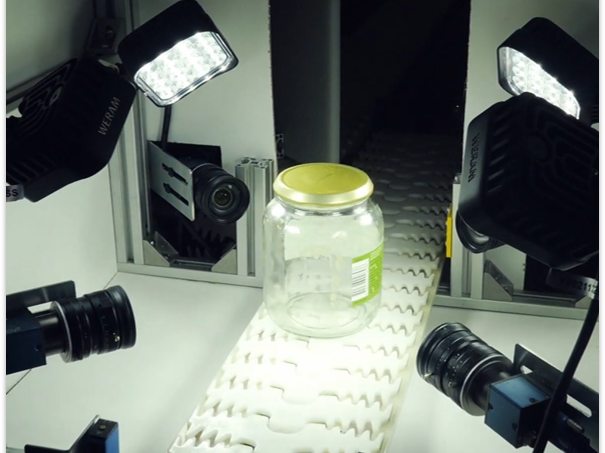

Vision

Using system knowledge in combination with directed, industrialized AI our vision algorithms can detect world variations and handle product variability.

Manipulation

Pick-and-place, sanding or dispensing, automation is possible! What is your challenge?

Communication

Communication algorithms are the key to unlocking the information that is available in your system; communicate with PLCs, instruct several brands robotic arms or talk to industrial PCs!

Our software is perfect for everyone who has variations in their industrial process!

Automating your process!

Core competencies

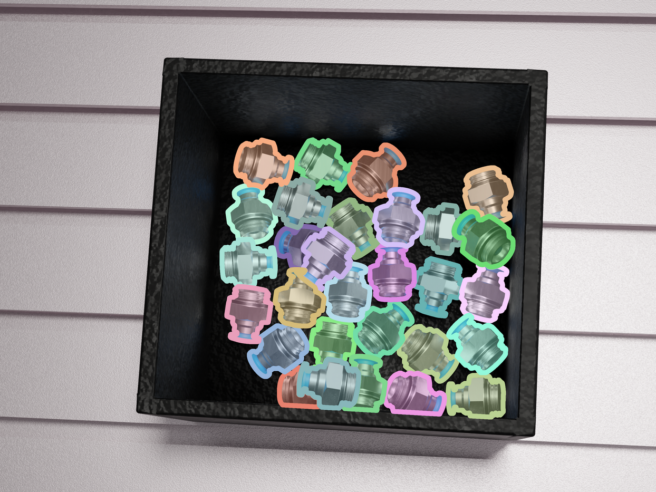

Synthetic data

Endless amounts of data with infinite customization opportunities, all within (robot)arm's reach.

Data driven vision

Using directed (synthetic) data, robust AI algorithms are obtained while still maintaining their speed and flexibility.

traditional vision

Solve or simplify a task by using knowledge of the environment and or the product, no data necessary!

System thinking

By looking at the bigger picture, not only the challenge at hand, better solutions can be found and potential future problems can be prevented.

Motion planning

When the robot uses detections there are no predefined movements. Path planning is used to guarantee a safe and fast robotic manipulation.

Communication

Robot manipulators, PLCs or industrial PCs: the desired hardware works with our software.

Contact Us

NEWCIRCLE TECHNOLOGIES was founded in 2019 with a passion for technology. From the beginning, the vision has been to incorporate modern technologies in industrial processes in order to improve and optimize products and services. Nowadays the focus lies on handling (product) diversity with computer vision.

Kastanjelaan 400

5616 LZ, Eindhoven

Netherlands